How Does Quality Assurance Differ From Quality Control?

It is easy to go confused past the departure between Quality Assurance (QA) and Quality Control (QC). Some use the terms interchangeably, although in that location is a notable difference between the ii.

No time to read? Listen to this commodity:

Both QC and QA can help your organization be compliant with the necessary regulations and produce the best products possible.

Thus, understanding both terms is increasingly important, especially if you piece of work with Quality Direction Systems in Life Scientific discipline industries similar Pharmaceuticals, Biotech, or Medical Devices.

This article covers the definitions of QA and QC, their objectives, in an infographic format.

Furthermore, you volition learn the primary difference between Quality Assurance (QA) and Quality Command (QC), and the purpose of both QA and QC within an Electronic Quality Management System (eQMS).

- What is Quality Assurance (QA)?

- What is Quality Control (QC)?

- Difference Between Quality Control and Quality Assurance

- QA and QC Supporting System

- QA and QC in the Quality Management System

What is Quality Assurance (QA)?

The ISO 9000:2015 standard, clause iii.3.six defines Quality Assurance as:

"part of quality management (3.3.4) focused on providing confidence that quality requirements (three.6.v) volition be fulfilled"

Put differently, Quality Assurance (QA) relates to a set of planned activities within the product manufacturing process that ensure the condom and the quality of the production.

What is Quality Control (QC)?

The ISO 9000:2015 standard, clause iii.3.seven defines Quality Control every bit:

"part of quality direction (3.3.iv) focused on fulfilling quality requirements (three.6.5)"

In other words, Quality Control (QC) refers to the systematic set of processes used to ensure that the product meets the required quality standards.

Quality Balls (QA) and Quality Control (QC) are necessary for your Quality Management System. Simply put, you lot cannot test for the quality of the output by focusing only on one or the other alone.

Difference Between Quality Control and Quality Balls

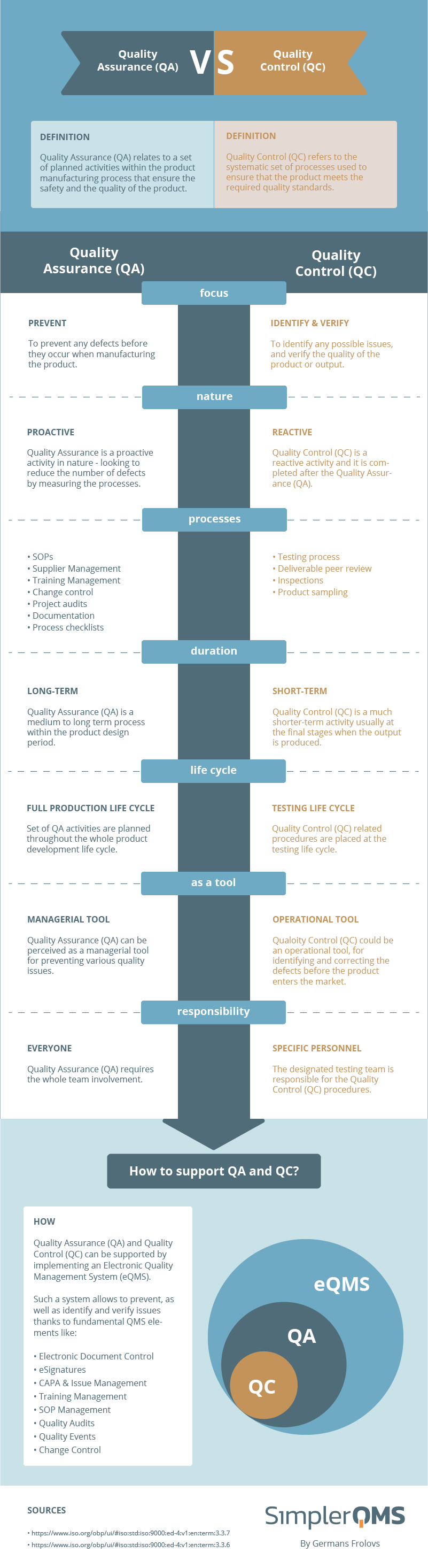

The infographic "Quality Control VS Quality Assurance" below illustrates the master differences between the processes.

If you would like to use this infographic, utilize the embed code below:

Focus & Nature of QC and QA

The primary objective of Quality Assurance (QA) is to forestall whatever defects earlier they occur when manufacturing the product. Quality Assurance (QA) is a proactive activity in nature – looking to reduce the number of defects by measuring the processes.

On the other hand, the main goal of Quality Control (QC) is to identify whatsoever possible issues, prevent them, if needed, and verify the quality of the production or output. Past its nature Quality Control (QC) is a reactive activity, which you would want to complete later the Quality Assurance (QA).

Processes & Orientation of QC and QA

Examples of Quality Control (QC) activities are process-oriented, as they aim to prevent quality defects. Therefore, some of the Quality Assurance (QA) examples include processes like:

- Post-obit Standard Operating Procedures (SOPs)

- Supplier Management

- Training Management

- Change control

- Project audits

- Documentation

- Process checklists

At the same fourth dimension, Quality Control (QC) deportment are product-oriented. Consequently, examples of Quality Control (QC) associated processes could be the following:

- Testing process

- Deliverable peer review

- Inspections

- Production sampling

Duration & Life Cycle of QA and QC

Typically, Quality Assurance (QA) is a medium to long-term process inside the product design menses. In contrast, Quality Control (QC) is a much shorter-term activity ordinarily at the last stages when the output is produced. Therefore, you would want to plan such a set of QA activities throughout the whole development life cycle. While QC-related procedures you would typically identify at the testing life bike.

QA and QC as Tools

Some other way of looking at Quality Balls (QA) and Quality Command (QC) would be to recognize what type of tools those are. For case, you tin can perceive QA as a managerial tool for preventing diverse quality problems. At the same time, QC could be an operational tool, for identifying and correcting the defects before the product enters the market.

Responsibility

Farther on, dissimilar kinds of personnel from your organization should be involved in both processes. Quality Assurance (QA) requires the whole team's involvement. While only the designated testing squad is responsible for the Quality Control (QC) procedures.

Your organization tin achieve Quality Assurance (QA) by putting into exercise a Quality Management Organization (QMS). This system will help with the prevention of quality issues in all departments of the firm. Furthermore, your company can attain Quality Control (QC) by finding & eliminating sources of quality bug via various activities and techniques like inspections, tests, and reviews, aimed to maintain and achieve quality.

QA and QC Supporting System

Y'all tin can support Quality Assurance (QA) and Quality Control (QC) by implementing an Electronic Quality Management Organisation (eQMS).

Such a system allows preventing, equally well as identify and verify issues thank you to primal QMS elements similar:

- Document Control

- eSignatures

- CAPA Management

- Supplier Management

- Training Management

- SOP Direction

- Template Management

- Equipment Management

QA and QC in the Quality Direction Arrangement

Quality Direction Organisation (QMS) focuses on optimizing the quality of the output and no wonder both Quality Assurance (QA) and Quality Command (QC) are the basis of a QMS. Moreover, together with the industry-specific quality legislations and standards, QA and QC make up the structure of the Quality Management System.

One of the fundamentals of ISO-9001, "continuous improvement" also suggests that the progress apropos Quality Balls (QA) never stops. This means that you should always have a disquisitional appraisal of your business firm'south Quality Balls (QA) System to ensure consequent improvements.

Final Thoughts

Both Quality Balls (QA) and Quality Command (QC) are terms many people utilise interchangeably. Withal, the difference between the two is significant. Y'all can see the main differences between QA and QC are visualized in the "Quality Assurance VS Quality Control" infographic.

Quality Assurance (QA) is a combination of activities throughout the manufacturing process that ensures the quality of the production. Consequently, Quality Command (QC) is a set of processes used to secure that the product meets the quality requirements. Although, both QA & QC utilize statistical tools that are explained in the book Quality Control with R (Cano et al. 2015).

The main bespeak of Quality Assurance (QA) is to foreclose any defects earlier they occur. Therefore, Quality Assurance (QA) is a proactive activity past its nature. On the contrary, Quality Control (QC) aims to identify any possible issues and verify the quality of the output. Inherently, Quality Control (QC) is a reactive action and information technology is conducted only after the Quality Assurance (QA).

How Does Quality Assurance Differ From Quality Control?,

Source: https://www.simplerqms.com/quality-assurance-vs-quality-control/

Posted by: macedocoundeplaid1949.blogspot.com

0 Response to "How Does Quality Assurance Differ From Quality Control?"

Post a Comment